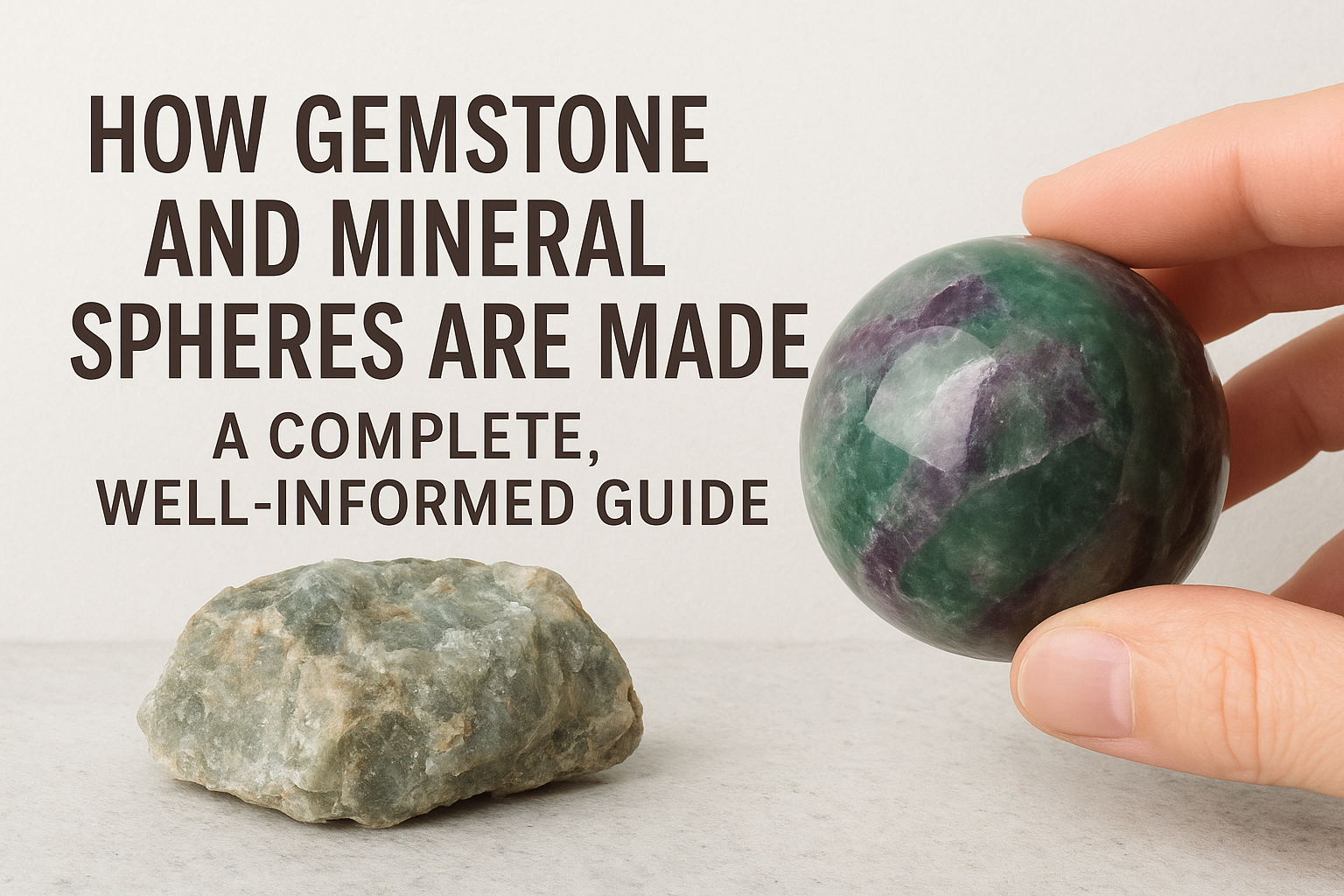

How Gemstone and Mineral Spheres Are Made: A Complete, Well-Informed Guide

Gemstone and mineral spheres are some of the most visually captivating forms in the lapidary world. Whether displayed in homes, used for metaphysical purposes, or collected for their beauty and symmetry, these perfectly rounded creations are the result of precise craftsmanship, specialized lapidary equipment, and an understanding of a stone’s natural structure.

This guide walks you through the entire process, step-by-step — from choosing rough material to achieving mirror-grade polish.

1. Selecting the Rough Material

Not every stone is suitable for sphere-making. Lapidaries look for:

✔ Solid, Cohesive Stone

- Avoid stones with deep fractures or crumbly textures

- Dense stones such as jasper, agate, quartz, fluorite, and obsidian work well

✔ Interesting Colors and Patterns

Spheres reveal a 360° view of:

- Banded layers

- Veins and inclusions

- Color zoning

- Chatoyancy or iridescence

Stones with internal surprises often make the most stunning spheres.

✔ Adequate Size

Rough needs to be larger than the desired sphere because significant material is removed:

- A 3-inch sphere may begin as a 4–5″ chunk of rough.

2. Cutting the Stone Into a Rough Cube

The first shaping stage is converting the rough rock into a cube or rectangular block.

Tools used:

- Diamond slab saw

- Trim saw

Why a cube?

- Each corner of the cube becomes the starting point for carving the sphere shape.

- It ensures a uniform base for the sphere machine.

The lapidary evaluates the orientation to highlight the best patterns and minimize cracks.

3. Preforming the Sphere Shape

This is where the cube begins to look rounded. Preforming is done using either:

Method A: Manual Grinding

Using:

- Diamond grinding wheels

- A bench grinder

- Angle grinder with diamond discs

The cutter removes corners and edges, producing a shape known as a rounded octahedron.

Method B: Using a Sphere Preforming Jig

This device holds and rotates the stone against grinding wheels, speeding up early shaping.

Goal at this stage:

- Remove all flat faces

- Establish a roughly spherical outline

The stone now resembles a lumpy sphere, ready for precision rounding.

4. Shaping With a Sphere Machine

A sphere machine is the key tool in lapidary sphere-making.

How It Works

A sphere machine typically uses:

- 3 motorized grinding cups

- Angled heads that rotate in synchronized motion

- Adjustable arms to hold the stone in center position

The stone rotates in all directions while grinding cups wear it down evenly.

Stages of Sphere Machine Work

- Coarse grinding (80–100 grit)

- Removes major irregularities

- Establishes the near-final shape

- Medium grinding (220–400 grit)

- Smooths the surface

- Removes coarse scratches

- Fine grinding (600–1200 grit)

- Prepares the stone for polishing

- Ensures uniform curvature without dimples or flat spots

Depending on hardness, this process can take hours to days.

5. Polishing the Sphere

Once perfectly shaped, the sphere is polished using:

Common Polishing Methods

✔ Diamond paste (8,000 to 50,000+ grit)

The most popular method; produces a glassy, mirror-like shine.

✔ Oxide polishes

Used depending on the mineral:

- Cerium oxide – ideal for quartz, obsidian

- Tin oxide – excellent for harder stones

- Aluminum oxide – good all-purpose polish

✔ Polishing pads or leather wheels

The sphere is held against the polishing surface until a high luster appears.

Polishing Challenges

- Overheating (can fracture stones like opal or fluorite)

- Uneven polish if the sphere machine isn’t adjusted correctly

- Certain stones, like malachite or calcite, require gentler polishing due to softness

6. Final Inspection & Finishing Touches

Before a sphere is considered complete, the lapidary inspects it for:

✔ Scratches

Even tiny scratches show up easily on polished spheres.

✔ Flat spots

A true sphere has no planar areas — even slight flattening is visible during rotation.

✔ Natural features

Depending on the stone:

- Internal fractures

- Veins

- Color zones

These aren’t flaws; they are part of the stone’s character.

7. Optional Additions

Many finished spheres include:

✔ Display Stands

Wood, acrylic, metal, or carved stone bases elevate the visual appeal.

✔ Identification Labels

Especially important for collectors or sellers.

✔ Stabilizing or Sealing

Some stones (e.g., chrysocolla or soft calcite) may be sealed to improve durability.

How Long Does It Take to Make a Sphere?

Time varies by hardness, size, and complexity:

- Small 1″ sphere: 1–2 hours

- Medium 3–4″ sphere: 4–10 hours

- Large 6–8″ sphere: Days of grinding and polishing

Why Spheres Are So Valued

Gemstone spheres are popular because:

- They showcase full patterning with no “front” or “back”

- Their symmetry reveals internal beauty evenly

- They hold cultural and metaphysical appeal

- They require more raw material and more skill than most lapidary shapes

A well-made sphere is the result of true craftsmanship.

Conclusion

Making gemstone and mineral spheres is a blend of art, engineering, and patience. The process requires high-quality rough, careful shaping, skilled machine work, and refined polishing techniques. Each completed sphere is a one-of-a-kind piece that reveals the full story of the stone’s natural beauty.

© Gems and Minerals Rock